KEA Shell Management System

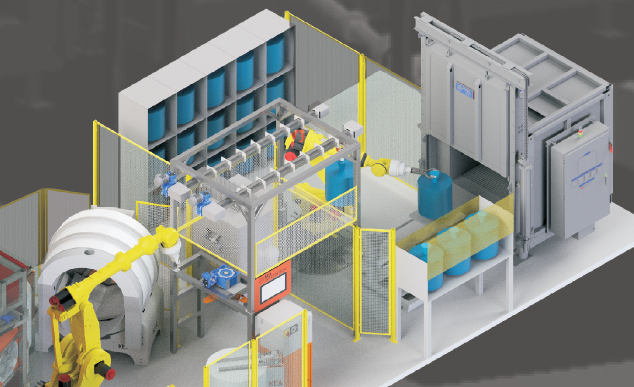

The KEA System for shell management is windows based touch screen PC specifically designed to supervise the shell manufacturing process in a fully automated shell room.

The KEA System for shell management is windows based touch screen PC specifically designed to supervise the shell manufacturing process in a fully automated shell room.

The KEA Automation Conveyor system is specially designed to suit customer requirements.

It is designed and manufactured with care and precision for the conveyor chain, to run smoothly enhancing the life of the mechanism.

KEA Automation flow coating machine is especially designed for smaller products and minimises the amount of slurry waste. It allows safe operation to be performed by any operator even using potentially hazardous yttria stabilised zirconia component slurries.

It has easily removable slurry dispersal trays.

The KEA Automation rainfall sander is designed and made for maximum heavy duty usage with efficient distribution of stucco material.

All models are available in many sizes to suit customer needs and requirements for manual or automatic environment.

KEA Automation slurry tanks are designed for heavy duty, long life, efficiency and consistent mixing of the slurry.

The standard heavy duty product range is available in many sizes with optional equipment for operation in manual or robotized environments.

KEA Automation has experience with many robot brands including Fanuc, ABB, Kawasaki and Kuka. KEA offers the same robot service for each brand including full integration, programming, training, aftersales support and servicing.

All robot brands can be fully integrated and supported with KEA Shell Management Systems providing a seamless robot processing solution with the production equipment.

KEA Automation can provide fully automated pouring solutions for new systems or upgrades of existing products.

Utlilising enhanced robot systems allows flexible process sequencing.

Abrasive wheel cut-off and belt grinding solutions from KEA Automation provide automatic cutting, degating and finishing of castings.

Utalising Fanuc robot technology, automatic programs ensure repeatability asnd accuracy of the cutting operation. Automatic pneumatic clamp actuation with bespoke tooling securely holds the tree for manipulation during operations