The system is interfaced via Ethernet to the robots, conveyor systems, shell drying and peripheral equipment.

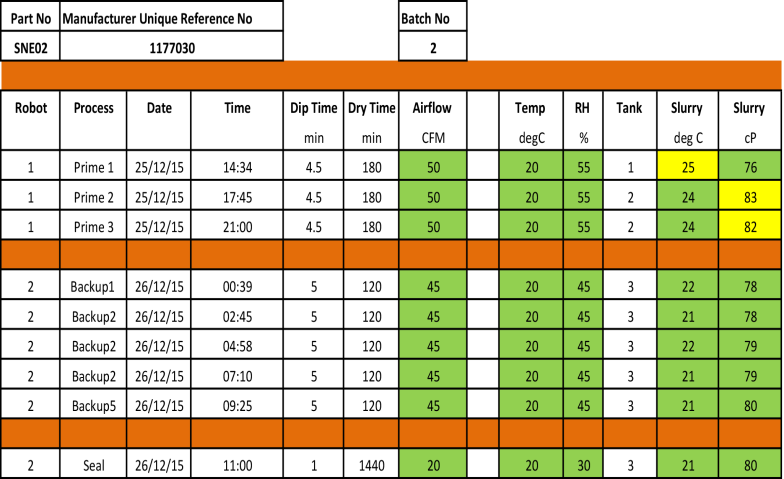

It provides control of day to day operation of the manufacturing process helping to eliminate process variability and optimise efficiency.

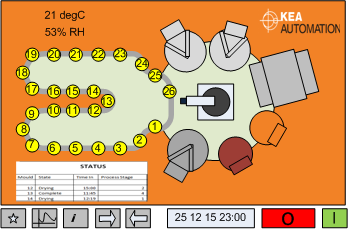

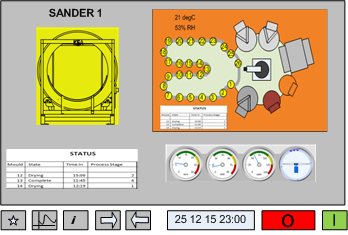

The System Status Screen shows a mimic of the entire system at a glance. The location of hangers and the process state of the shell is shown in real time to allow visualisation of the process and traceability of shell production with additional screens available to “drill down” to comprehensive data related to individual pieces of plant and equipment such as slurry tanks and sanders.

The conveyer designer screen allows the design of the conveyer shape for the shell management screen so the actual conveyer is represented.

The System Configuration Screen allows configuration of all options to suit the needs of the shell room. The number of hangers and conveyor levels are configurable together with ancillary equipment such as sequence control of drying fans.

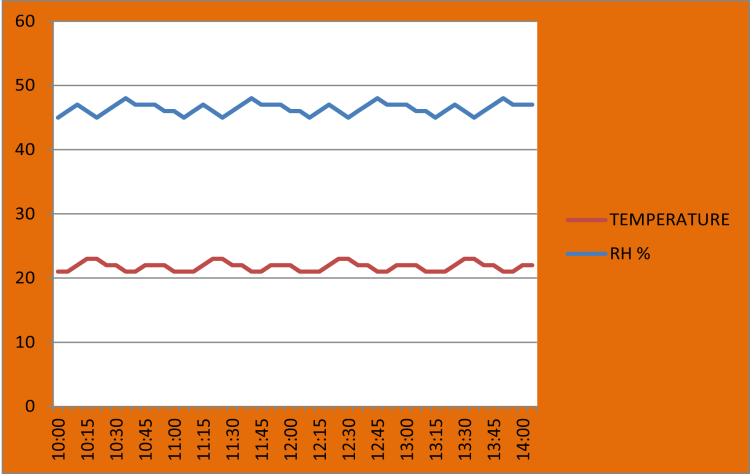

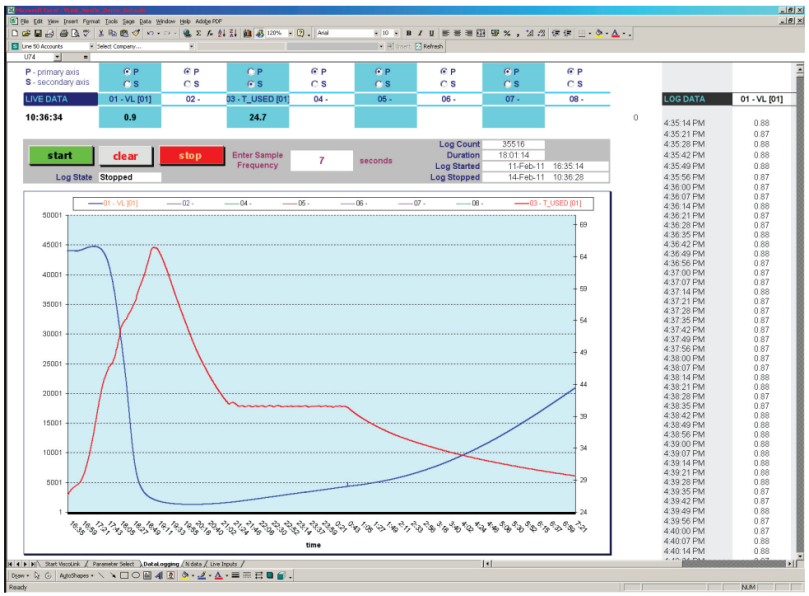

Total environmental condition logging is available as standard with the option of central PC based control of the room conditions.