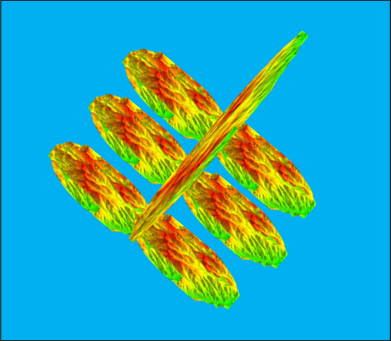

The Kea Automation Shell Vision Thickness measurement system utilises the latest innovations in laser scanning and image processing to generate a graphical representation of the thickness of the ceramic coating on the shell at any point in time to a resolution of 20µm.

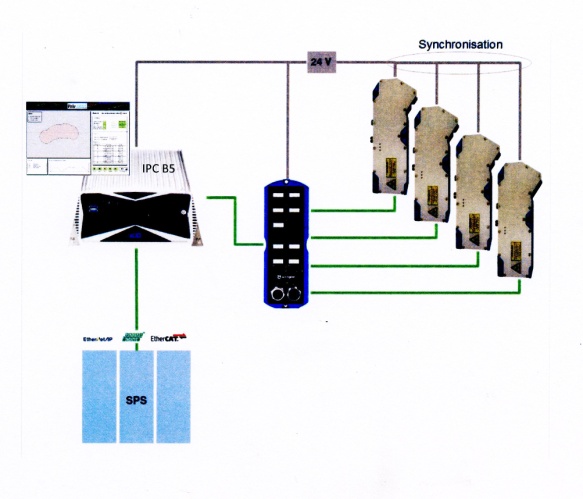

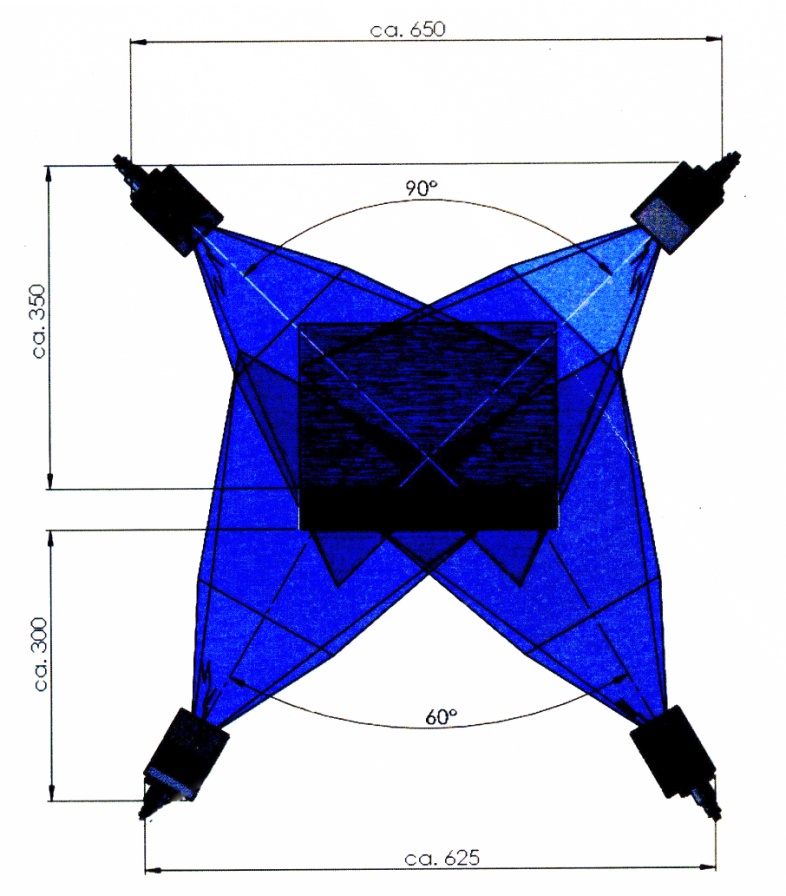

The scan station comprises multiple laser scanning cameras arranged around the shell to rapidly image the shell and pass the data to the control module for processing

The shell is scanned in process by a scan station integrated into the conveyor system and the size of the shell is measured in 3D enabling accurate measurements of the coating thickness to be made by reference to the previous scan result.

Integrated into the Shell Management system, the scanning system provides the ability to dynamically control dipping and sanding to maintain precise coating thickness deposition. If localised thickness variations are found in a shell an alarm will be generated and the system will enter a hold state to prevent possible yield loss.